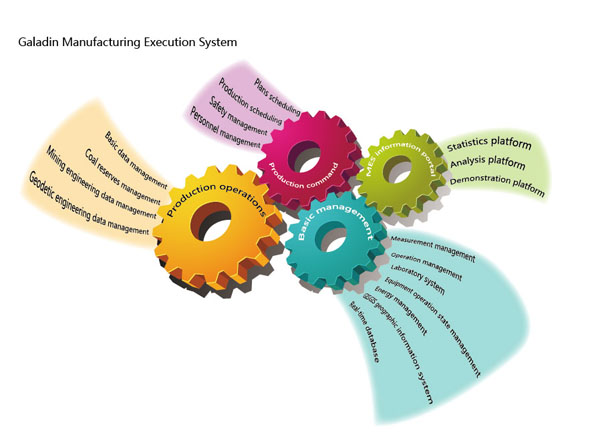

Galadin Manufacturing Execution System (hereinafter referred to as Galadin MES) is a core business system for coal companies. On the one hand, the system is responsible for turning the management decisions into actual production demand and then directing daily productive activities. On the other hand, as the command center for coal production, it manages the docking with all underground professional automatic control systems, on-site safety monitoring and production direction and dispatching.

Background

As during the real coal production, coal mining, excavation, transportation, power supply and other tasks go in tandem, the needed raw materials are various. Moreover, fine management is impossible since there is no absolute quantitative correspondence between raw materials and the excavation and transportation of coal. Galadin MES aims to save energy, reduce consumption and costs and improve efficiency through informatized and fine management of production process on the premise of the safety production of “one ventilation and three preventions” (mine ventilation, preventions of gas, coal dust and mine fire).

Functional Modules

(1) Production planning

The responsibilities of this function module are: first, compiling and reviewing production plans, succession production plans and supporting plans about equipments, materials and power and submitting them (plus the related schedule, fund planning and energy consumption) to the mining group; second, managing the yearly, monthly and weekly plans for coal production; third, adjusting production plans timely by considering the realities of coal production, transportation, sales and the maintenance of equipments and supporting infrastructure and reporting the plans to the group so as to enable it to achieve macro-control of production.

(2) Production Scheduling

Through Galadin MES, enterprises can conduct dispatch and coordination according to the production realities and the monthly, weekly or daily excavation and washing-dressing plans based on coal production plans and succession plans with a view to ensuring the safety, continuity stability of coal production and coordinate with the group to achieve the balance and adjustment of plans.

(3) Safety Management

The management of coal mine safety consists of two aspects. The first is the safety supervision of the internal coal production including the standard inspection of safety quality and the supervision of the entire process of risk management. Galadin MES supports monthly standard inspection and grading of safety quality and internal classification of coal mine, hence helping enterprises to understand the overall safety state of periodic mining. Moreover, the system supports supervision of the entire process of safety risk management, helping enterprises to grasp the overall management of safety risks in coal mines and the analysis of statistics according to their origin, profession and classification. The second is the safety monitor of coal mines based on the three coal-mining systems, underground monitor system and automatic ground monitor system which includes video surveillance, running monitor, real-time collection and analysis of safety information about the coal production in terms of environment monitor and beam tube monitor and warning. Galadin MES provides support for safety decision-making through the two aspects of safety management.

(4) One Ventilation and Three Preventions

Galadin MES can achieve the overall management of one ventilation and three preventions in daily production including inspection of gas, wind measurement and dust measurement. It can also achieve the generation and review of reports about gas, wind measurement and dust measurement, the log and safety inspection of infrastructure for one ventilation and three preventions like air dust and the log and check of mining machines such as gas detection instrument.

(5) Safety Training

Galadin MES can manage the certificates of certified staff and support certificate training for staff in need of job certification in coal mines, including formulation and execution of coal-mining safety training plans, specifically, it includes compilation and review of training plans, compilation and issuance of training notifications, examination of training application and feedback of training results. The system is also able to create statistical reports about staff certification according to training plans and their implementation.

(6) Technical Management

Galadin MES realizes management of technical files and information execution and management of five notifications (holing-through, head-blocking, mining-stopping, holing and return-to-work)

(7) Coal Reserves Management

Galadin MES boasts functions of reserves unit management, parameter setting, results management, reserves evaluation, annual reserves report and reserves reports.

(8) Management of Mining Project Information

Based on the GIS platform technology, Galadin MES is able to manage the basic information of mining projects.

(9) Management of Cadastral Survey Data

Based on the GIS platform technology, this module is responsible for the management of cadastral survey data and various professional graphics and data about the mine geology.

(10) Event State Recording

GIS platform technology allows management personnel to start emergency plans according to safety events and offers guidance on timely disposal to related staff.

Features

(1) High degree of integration

As Galadin MES adopts Industrial Gateway OPC server, it can quickly integrate not only the automatic control systems with OPC protocol as external interface, but also the automatic control systems with hardware communication protocol as external interface. Moreover, given the distinctiveness of the mining operation (for example, systems of safety, staff and output offer external interfaces in the form of document), the system provides a specialized service of file collection. Based on real-time data base technology and configuration technology, Galadin MES also provides real-time data service, dynamic reporting service and data analysis service, which makes the data sources more accurate and data timelier so as to effectively facilitate the safety and efficient production of users.

(2) User-friendly report design and analysis tools

By integrating reporting tools, Galadin MES enables generation of complex reports for groups and coal mines, fast and accurate processing of complex reports and the display through graphs such as star chart and line chart in light of the features of a report, which makes reports easy to understand and helps improve the customer acceptance.

(3) Convenient function management

Galadin MES supports the import and export of excel files, provides multi-classification retrieval and statistics compilation of various kinds of information and the printing of reports. It can help the management personnel of coal production in an effective and quick way.

(4) Smooth convergence of business interaction and collaboration

The production platform is designed and developed for coal mine groups and share-holding coal mine enterprises on the basis of ESB technology and LDAP protocol to support the application of groups and coal mines. It supports flexible and limitless extension of groups’ subordinate mines in terms of organization and close collaboration on daily safety and production between groups and their subordinate coal mines in terms of operation. As for content, it consists of system default setting, maintenance of basic information, presetting of approval procedure and the maintenance of the basic information used by the production execution system.

(5) A data platform based on real-time data bases

Galadin MES can completely avoid the automatic isolation of bottom production and the information isolation of production management.

(6) A Web application system based on integrated portal technology

Galadin MES can customize safety production monitor, production management, comprehensive production commend module and emergency commend system for coal enterprises. It is the prime solution for coal enterprises to achieve production informatization.

Key Benefits

Galadin MES designed by GreatWe aims to achieve informatized management of coal production and mining operation and to save energy, reduce consumption and costs and improve efficiency through fine management of production process on the premise that safety is ensured.

●By integrating the three coal mine systems, underground monitor system and automatic ground monitor system, Galadin MES can get field data and detect problems timely so as to avoid disasters and events and to effectively reduce the loss of personnel and property. The system also enables management personnel of production safety at bureau and mine levels to grasp the realities of production safety in mines in a timely way, hence providing reliable basis for decision-making over proper dispatching and safety supervision of production in mines.

●Through real-time information portal, Galadin MES can optimize the plan dispatching and supervision of daily production, resource distribution and production process according to the real-time data from industrial monitor system, real-time images from video surveillance and the realities of comprehensive production and the resources such as mine workers and conduct fine management of production process on the premise that safety is ensured.

●Galadin MES can improve the management of coal minces. As Galadin MES integrates the real-time monitor data about the field work in mines and the operation information of production safety and as the production management and safety management of mines can be conducted in specific district team and class team, Galadin MES can greatly enrich the data for decision-making in leadership. Moreover, based on MES, leaders can direct the field work and realize fine management and circuit management by getting the real-time data of bottom sites which can be sent to support their decisions and by transmitting the decisions to the bottom promptly.

●As a full-fledged coal-mining safety training system has set up, Galadin MES supports the safety training of certified staff at various levels from group, mine to department, the management of questionnaire related to training and notification, the management of education and teaching resources, management of training and assessment certification and statistical analysis of safety training, hence realizing the informatized management of coal-mining safety management.

●Galadin MES makes full use of the advantages of network technology. It provides professional data communication, data backup, operation analysis and expert guidance to users through corporate WAN and the Internet and offers remote maintenance and updating of software system, which fully reflects its production-orientation and its purpose of serving the production of mines.

Potential Client

As Galadin MES is equipped with SOA (Service-Oriented Architecture), a practice which has been proven to be the best in the industry, it ensures the compatibility and openness of the entire system. Combined with the unlimited expansion composition and the flexible configuration in work process, Galadin MES is applicable to enterprises from as small as a single coal mine to as large as a coal mine group for production safety, safety management, safety supervision and other business.